This article will focus on internal and external influences that are sometimes hard to determine but can affect the overall weighing results.

Mass measurements are carried out worldwide at all times, from the kilogram of potatoes to the ounce of gold to the ton of nitrogen, and every measurement gets carried out with the correct precision. Metrology services and other local calibration authorities ensure that the weighing is linked to the International Prototype Kilogram. This traceability chain will guarantee that one kilogram in Sydney is identical to a kilogram in Shanghai or San Diego and ensures that the transactions can be carried out uniformly across all borders. Providing the proper unit of mass doesn’t guarantee an adequate measuring result.

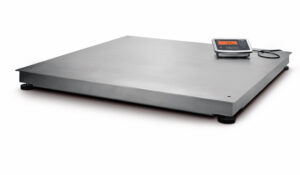

On the way to an actual value, all kinds of factors affect the outcome, and anyone who is professionally involved in weighing should know the essential ones. The journey starts with the proper weighing equipment, installation, and calibration and ends with other external factors such as heat or wind. This article will focus on internal and external influences that are sometimes hard to determine but can affect the overall weighing results. The disrupting influences range from dynamic forces to air pressure and should be considered when precise and repeatable measurement results are requested. Read on to learn more!

Weighing Instruments are Now Designed for Measuring Mass

Advanced electronic scales determine the overall mass of an object by the effect that the gravity of Earth has on this object. Because the gravitational acceleration “g” depends on the particular location, any electronic scale’s sensitivity must be re-adjusted every time they are moved to a different location. For example, the gravitational acceleration at the equator is around 0.5% less than that at the earth’s poles.

Applications of Scales

A scale can not only be used to determine the weight, but it could also be used to measure other values that are entirely related to mass, like density, piece counts of objects having the same weight, surface tension, and other forces. When measuring force, you have to ensure that its direction is the same as that of the instrument’s direction of measurement, which is entirely vertical.

Size and Shape of the Application

A common application of industrial weighing is silo as well as vessel weighing. Most experiments were undertaken to help measure the forces the flowing air exerts, for example, on an upright standing vessel. The results show that the forces depend on

- The shape of the vessel

- The smoothness of the surface

- Size of the vessel

CONTACT THE SCALE PEOPLE FOR WEIGHING EQUIPMENT AND CALIBRATION SERVICES!

Since 1956, The Scale People have earned a reputation as the best service provider for calibrating and repairing weighing equipment in the mid-Atlantic area. Our sales team can help you to find the best weighing equipment for your application. We currently have offices in Columbia, MD, and Newport News, VA, but we offer our services nationwide. Over the years, we have built many satisfied clients from various industries, including pharmaceutical, food and beverage, and government manufacturing. We are a fully ISO/IEC 17025:2017 accredited service company offering calibration for balances, scales, dynamometers, force measurements, test weights, pipettes, and more. All our services have a 100% satisfaction guarantee. We’re only a phone call away at +1 (800) 451-9593. Follow us on Facebook, Twitter, and LinkedIn to learn more about our work.