Load cells play a serious role in determining the flexibility, strength, elasticity, ductility, and durability of all materials.

Materials testing is the main process of measuring the physical makeup and behavior of objects and substances under different sets of conditions. The purpose of this testing is to make sure that the safety and reliability of structures, products, and constituent materials are all okay. Stain gauge load cells are crucial components in the materials testing process. Since they’re used to measure the force that is applied to a material during testing, load cells play a serious role in determining the flexibility, strength, elasticity, ductility, and durability of all materials. Read on to learn more!

Material Testing with Load Cells

Material testing incorporates the use of special machines to perform every kind of test. Load cells are important components of these machines. Using different techniques, a controlled force is applied to the material that is being fully tested. It is the load cell component of a machine that helps provide force measurement data for your test. The parameters of the test force will depend on the materials and characteristics that are being measured. A few forces include compression, tension, torsion, and shear.

Usual Types of Material Testing

The most common kinds of tests include tensile, compression, fatigue, bending, torsion, impact, and peel testing as well. The choice of a truly suitable load cell for every type of test depends on the kind of material being tested and the desired level of accuracy.

Peel and Tensile Testing

In peel and tensile testing, a tension load cell like a tension link or S-type would then be used to measure the amount of tension force that is applied to the material being tested. The results of tensile tests could be used to determine the material’s overall tensile strength, tensile modulus, Poisson’s ratio, and elongation. Peel testing is also used to ascertain the initial peak force, average force over a seal, and peel strength of materials.

Compression Testing

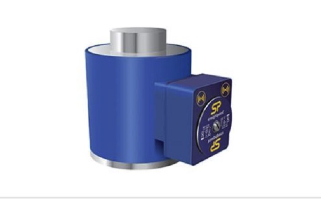

Compression load cells are used with compression testing and impact testing to help measure the force applied to a material as it is compressed – for example, load cells like beam, button, canister, and donut load cells. Compression testing will determine the test material’s limits, yield points, yield strength, and compressive strength, too. Impact testing measures the actual ability of an object to resist high-velocity loading fully and also determines the amount of energy that is absorbed for fracturing a material.

CONTACT THE SCALE PEOPLE FOR WEIGHING EQUIPMENT AND CALIBRATION SERVICES!

Since 1956, The Scale People have earned a reputation as the best service provider for calibrating and repairing weighing equipment in the mid-Atlantic area. Our sales team can help you to find the best weighing equipment for your application. We currently offer our services nationwide. Over the years, we have built many satisfied clients from various industries, including pharmaceutical, food and beverage, and government manufacturing. We are a fully ISO/IEC 17025:2017 accredited service company offering calibration for balances, scales, dynamometers, force measurements, test weights, pipettes, and more. All our services have a 100% satisfaction guarantee. We’re only a phone call away at +1 (800) 451-9593. Follow us on Facebook, Twitter, and LinkedIn to learn more about our work.